Floor Paint Solutions for Welding and Fabrication Facilities

Introduction

Welding and fabrication facilities require durable and high-performance floor coatings to withstand extreme heat, heavy machinery, metal debris, and chemical spills. Standard floor paints are not suitable for these environments as they degrade quickly under intense operational conditions.

Selecting the right industrial floor paint ensures safety, longevity, and resistance to common hazards like sparks, welding slag, and impact damage. This guide explores the best floor coatings for welding workshops, their key features, and how to apply and maintain them for long-term performance.

Read more...The Best Floor Paint for High-Traffic Areas

Key Takeaway

- Assess Your Industry Needs – Choose paint based on traffic, exposure to chemicals, and durability requirements.

- Consider Environmental Factors – Temperature, humidity, and UV exposure affect performance.

- Work with Reputable Suppliers – Purchase from trusted sources like GZ Industrial Supplies for high-quality industrial floor paints.

Epochem Polyurethane Floor Paint

Key Requirements for Floor Paint in Welding & Fabrication Facilities

Heat and Fire Resistance

Welding areas generate extreme temperatures, sparks, and molten metal, making it crucial to use heat-resistant floor coatings. Without the right paint, floors can scorch, crack, or catch fire, leading to safety hazards and costly repairs.

Recommended Coatings:

- Epoxy-based high-heat-resistant paints for metal fabrication areas.

- Polyurethane coatings that withstand sparks and welding slag.

- Ceramic-based coatings designed for extreme temperatures.

Impact and Abrasion Resistance

Welding and fabrication workshops handle heavy steel parts, tools, and machinery, which cause scratches, dents, and wear over time. A weak floor coating will chip, crack, and degrade, making repairs frequent and expensive.

Best Coatings for Impact Resistance:

- Industrial-grade epoxy coatings for high-load-bearing capacity.

- Polyurethane topcoats that resist heavy impact and friction.

- Concrete densifiers that reinforce floors against shock damage.

Chemical and Oil Resistance

Metal fabrication and welding involve exposure to oils, lubricants, and cleaning solvents, which can weaken floor coatings over time. Chemical spills can lead to:

- Paint peeling and blistering.

- Slippery surfaces that cause accidents.

- Permanent stains and structural damage.

Ideal Chemical-Resistant Coatings:

- Solvent-resistant epoxy paints for machine shops.

- Polyaspartic floor coatings for chemical-intensive environments.

- Oil-repellent polyurethane sealers for workstations.

Anti-Slip and Safety Features

In industrial welding spaces, maintaining a non-slip work surface is essential for worker safety. Metal dust, grease, and welding residue can create hazardous walking conditions, increasing the risk of falls.

Solutions for Anti-Slip Protection:

- Textured epoxy coatings with slip-resistant aggregates.

- Polyurethane coatings with silica grit for traction.

- Zoned floor markings to define safe walking paths.

EPOCOAT 304/305 Floor Paint

Types of Floor Paint Solutions for Welding & Fabrication Workshops

Epoxy Floor Coatings

Epoxy coatings are one of the most durable solutions for welding and fabrication facilities. They provide:

- Superior resistance to heat, impact, and chemicals.

- Seamless application that prevents dust and debris buildup.

- Easy maintenance with long-lasting performance (5–10 years).

Best for:

- High-traffic welding areas.

- Heavy fabrication workshops.

- Automotive and metal processing plants.

Polyurethane Floor Coatings

Polyurethane coatings are known for their abrasion resistance and flexibility, making them ideal for areas exposed to mechanical movement and temperature variations.

- Resistant to cracking under heavy loads.

- Withstands oil, solvents, and industrial cleaning chemicals.

- Available in gloss and textured finishes for anti-slip safety.

Best for:

- Machine shops and metalworking stations.

- Facilities with fluctuating temperatures.

- Work areas requiring fast-drying coatings.

Anti-Slip & Textured Coatings

Anti-slip coatings enhance safety in welding environments by reducing the risk of slips and falls caused by oil spills, metal dust, and welding slag.

- Textured epoxy coatings include silica or quartz aggregates for extra grip.

- Polyurethane-based slip-resistant coatings provide flexibility and impact resistance.

- Floor marking coatings help define safe walkways, restricted zones, and equipment areas.

Best for:

- Walkways and designated safety zones.

- Heavy-duty workstations handling metal cutting and fabrication.

- Industrial environments with high moisture or oil exposure.

High-Temperature Ceramic Coatings

Some welding shops regularly expose floors to extreme heat and molten metal droplets. Ceramic-based coatings provide thermal resistance while preventing cracking, scorching, or fire hazards.

- Designed to withstand temperatures up to 1,500°F (815°C).

- Ideal for welding booths, furnace areas, and plasma cutting stations.

- Enhances abrasion and impact resistance for high-wear environments.

Best for:

- Heavy welding stations and foundries.

- Facilities with frequent grinding, metal cutting, and flame exposure.

- Areas requiring extra fireproofing and heat insulation.

Epoxy Resin Epochem 105, 5kg Keg

Application Process for Industrial Floor Paint

Surface Preparation

Proper surface preparation ensures maximum adhesion and long-lasting performance of industrial floor coatings.

Preparation Steps:

- Remove old coatings and contaminants using grinding or chemical stripping.

- Clean thoroughly to remove oils, grease, and dust before application.

- Repair cracks and imperfections with epoxy fillers before painting.

- Ensure proper moisture levels, as damp floors can lead to paint failure.

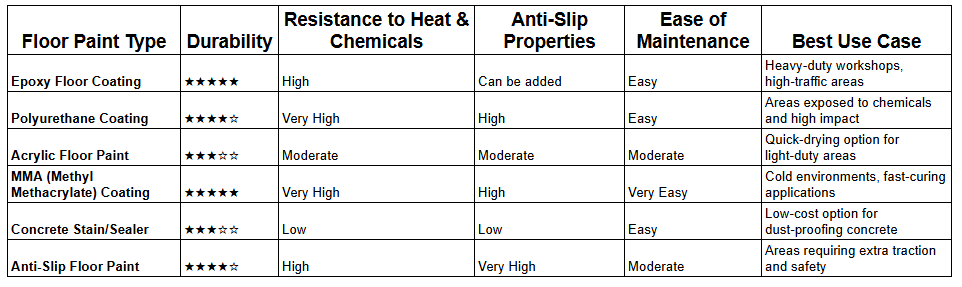

Comparison of Floor Paint Solutions for Welding and Fabrication Facilities

Choosing the Right Application Method

The correct application technique depends on facility size, coating type, and drying requirements.

Common Methods:

- Rolling: Best for small workstations and touch-up applications.

- Spraying: Ideal for large areas, offering fast coverage and even layers.

- Troweling: Used for thick coatings and reinforced protective layers.

Drying and Curing Time

Industrial floor coatings require proper curing to achieve full strength and resistance.

- Epoxy floors: 24–48 hours for light traffic, 7 days for full curing.

- Polyurethane coatings: Fast-drying, ready in 12–24 hours.

- Ceramic coatings: Requires heat curing in some applications.

Best Practices:

- Keep areas free of dust and debris during the curing process.

- Allow proper ventilation to speed up drying.

- Avoid heavy machinery or welding work on freshly painted surfaces for at least 72 hours.

Epoxy Catalyst, Epochem 205, 5kg keg

Maintenance and Longevity of Industrial Floor Paint

Routine Cleaning & Spill Management

Regular cleaning extends the life of floor coatings and prevents chemical damage.

- Sweep daily to remove metal shavings and dust.

- Mop with pH-neutral cleaners to maintain the coating’s integrity.

- Immediately clean up oil and chemical spills to prevent surface degradation.

Periodic Recoating & Repairs

Over time, high-traffic welding zones may require reapplication or repairs to prevent deterioration.

- Inspect floors every 6–12 months for signs of wear, chipping, or cracks.

- Apply clear topcoats to refresh protective layers and enhance durability.

- For severe damage, use floor grinders and reapply epoxy coatings.

Frequently Asked Questions

1. What type of floor paint is best for welding and fabrication facilities?

Epoxy and polyurethane floor coatings are the best options for welding and fabrication workshops. They provide high durability, chemical resistance, and heat tolerance, ensuring long-lasting protection for the floor.

2. How do I prepare my workshop floor before applying industrial floor paint?

Proper surface preparation involves cleaning the floor, removing oil and grease, repairing cracks, and ensuring the surface is dry before applying the coating. A primer may also be needed for better adhesion.

3. Can industrial floor paint withstand welding sparks and heavy machinery?

Yes, high-quality industrial floor paints, such as epoxy coatings, are designed to withstand welding sparks, heat, and heavy machinery impact, reducing wear and tear over time.

4. How often should I reapply floor paint in a welding facility?

The reapplication frequency depends on the level of foot traffic, exposure to chemicals, and wear. Typically, epoxy coatings last between 5-10 years, while polyurethane coatings may need touch-ups sooner in high-traffic areas.

5. Where can I buy high-quality industrial floor paint in Nigeria?

You can purchase durable and reliable industrial floor paint from GZ Industrial Supplies, a trusted supplier of premium coatings for welding and fabrication facilities.

Related Articles

The Pros and Cons of Using Water-Based vs. Oil-Based Floor Paint

The Ultimate Guide to Preparing Your Floor for Painting with Floor Paint

Conclusion

Choosing the right floor paint for welding and fabrication facilities is essential for ensuring safety, durability, and efficiency. A well-coated floor resists welding sparks, chemical spills, and heavy machinery, reducing maintenance costs and enhancing workplace safety. By selecting high-quality coatings like epoxy or polyurethane, you can create a more productive and long-lasting work environment.

For top-quality industrial floor paint solutions that meet the demands of welding and fabrication facilities, visit GZ Industrial Supplies today and explore a wide range of durable coatings tailored for your workshop needs!

Recent Posts

-

The Best Water Pumps in Nigeria 2025 Reviews

Introduction Water pumps have become so essential in the current world and every household should ha …Apr 28, 2025 -

Top 5 OBD2 Scanners for DIY Car Diagnostics in 2025

Top 5 OBD2 Scanners for DIY Car Diagnostics DIY car maintenance is booming in 2025, and having the r …Apr 26, 2025 -

Agricultural Sprayer and its uses

Introduction Agricultural sprayers are a special type of farm equipment used for applying liquid sub …Apr 25, 2025