Guide to Buying Industrial Floor Paint in Nigeria

Introduction

Selecting the right industrial floor paint is crucial for businesses across Nigeria, whether you're running a warehouse, factory, automotive shop, or a large-scale manufacturing facility. Industrial floors withstand significant abuse from heavy machinery, chemical spills, constant foot traffic, and extreme environmental conditions. Choosing a suitable industrial floor paint enhances durability, improves safety standards, reduces maintenance costs, and boosts your facility’s overall appearance and operational efficiency.

This comprehensive guide will help you understand the key considerations in purchasing industrial floor paint and ensure you make an informed decision tailored to your specific needs.

Read more...Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Key Takeaway

- Choose the Right Type – Epoxy, polyurethane, and acrylic paints offer varying levels of durability, chemical resistance, and finish quality for industrial floors.

- Consider Environmental Factors – Temperature, humidity, and exposure to chemicals or heavy machinery influence the best choice of floor paint.

- Surface Preparation is Crucial – Proper cleaning, degreasing, and priming ensure strong adhesion and long-lasting results.

- Durability & Maintenance – Invest in high-quality industrial-grade paint that withstands high traffic, abrasion, and chemical spills with minimal maintenance.

Understanding Industrial Floor Paint

What is Industrial Floor Paint?

Industrial floor paint is a specially formulated coating designed to protect and enhance the functionality of industrial floors. Unlike regular paints, these coatings offer increased resistance to abrasion, chemical exposure, moisture, and heavy impacts. They also improve safety by providing anti-slip surfaces and clear demarcation lines, essential for industrial environments.

Key benefits of industrial floor paint include:

- Enhanced durability and lifespan of floors

- Improved safety through anti-slip properties

- Easy cleaning and maintenance

- Chemical and moisture resistance

- Improved workplace aesthetics and professional appearance

Common Types of Industrial Floor Paint

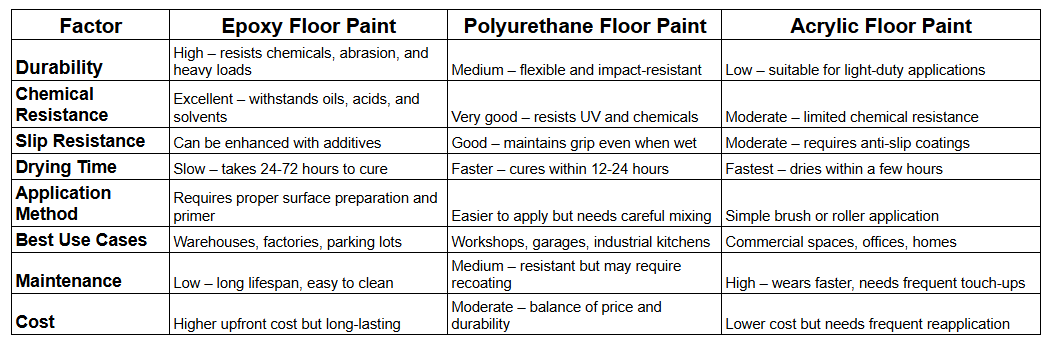

Understanding the available paint types will help you select the most suitable one for your industrial space:

Epoxy Floor Paints:

- Offers outstanding durability and resistance to heavy traffic, chemicals, and moisture.

- Ideal for warehouses, factories, and automotive workshops.

Polyurethane Coatings:

- Provides excellent UV resistance and flexibility.

- Suitable for indoor and outdoor settings with high foot traffic or heavy machinery.

Acrylic Paints:

- Cost-effective and quick-drying; suitable for light-to-medium duty floors.

- Ideal for storage areas, utility spaces, or areas requiring regular repainting.

Anti-slip and Specialized Coatings:

- Specifically designed for environments requiring additional safety, like ramps, loading docks, or areas prone to wetness.

Epochem Polyurethane Floor Paint

Factors to Consider When Buying Industrial Floor Paint

Choosing the right industrial floor paint goes beyond simply picking a brand or type. To ensure you select the most effective product, consider the following factors:

Floor Usage and Traffic Levels

Evaluate the type and level of activity your floor regularly experiences:

- Light Traffic: Areas with minimal activity may require basic acrylic or less durable epoxy paints.

- Medium Traffic: Areas with moderate foot traffic or occasional vehicle movement benefit from standard epoxy or polyurethane coatings for better abrasion resistance.

- Heavy Traffic and Machinery: Facilities handling heavy equipment, machinery, and continuous traffic should opt for high-performance epoxy or polyurethane coatings, ensuring maximum durability and lifespan.

Resistance Requirements

Assess the environment in your facility and determine the resistance your floor paint must have:

- Chemical Resistance: Chemical-resistant floor paints protect floors against corrosive substances and chemical spills, ideal for factories and chemical plants.

- Moisture and Water Resistance: High-moisture areas require coatings with excellent moisture resistance to prevent peeling, bubbling, and mold growth.

- Temperature and Abrasion Resistance: Consider paints designed to withstand high temperatures, heavy abrasion, and continuous friction, ideal for manufacturing environments.

Guide to Buying Industrial Floor Paint in Nigeria – Comparison Table

Recommended Industrial Floor Paint Brands and Suppliers in Nigeria

Choosing reputable brands and suppliers guarantees quality, durability, and value for money. Some of Nigeria’s most trusted industrial floor paint brands include:

- Epochem Epoxy Coatings: Known for durability, chemical resistance, and ease of application.

- Sigma Coatings: Offers high-quality epoxy and polyurethane paints ideal for industrial and commercial applications.

- Jotun Coatings: Renowned for reliable, long-lasting, and easy-to-maintain industrial flooring solutions.

Trusted Suppliers:

GZ Industrial Supplies: A top supplier offering a wide selection of high-quality industrial floor paints, primers, and application tools across Nigeria, ensuring quick delivery and professional advice.

You can buy the best Epoxy Flooring materials in Nigeria from the offices below:

GZ Industrial Supplies Ikeja

18 Adesina Street, Off Obafemi Awolowo Way,

Ikeja, Lagos.

Tel. +234 8181069339, +234 7031515985, +234 8060907072

WhatsApp: +234 8181069339

GZ Industrial Supplies Lekki

Suite 10, Olive Plaza by Osapa London Bus Stop,

Lekki, Lagos

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies Apapa

10 Apapa Oshodi Expressway, Coconut Bus stop Opposite Total Jetty,

Apapa, Lagos

Tel. +234 8181069339, +234 7031515985, +234 8060907072

GZ Industrial Supplies Port Harcourt

238 Aba Road, Onyejieke’s Plaza beside Fidelity Bank,

Rumuogba, Port Harcourt.

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies Calabar

30/32 Ndidem Usang Iso Road,

Marian, Calabar.

Tel. +234 8181069339, +234 8053390169 +234 8060907072

GZ Industrial Supplies ABuja

Shop 016, Zitel Plaza, Plot 227 P.O.W. Mafemi Cres. Utako, Abuja

Tell. +234 8053390161,+234 9121740191

GZ Industrial Supplies Ogba

79 Yaya Abatan, by College Road

Ogba, Lagos

Tel. +234 8181069339, +234 8053390169 +234 8060907072

Epoxy Resin Epochem 105, 5kg Keg

Step-by-Step Guide to Purchasing Industrial Floor Paint

To make the purchasing process seamless and beneficial, follow these practical steps:

Step 1: Identify Your Requirements

Determine the traffic level, environmental conditions, and specific resistances needed for your facility.

Step 2. Consult Experts and Suppliers

Discuss your requirements with reputable suppliers (like GZ Industrial Supplies) who offer professional guidance tailored to your needs.

Step 3. Evaluate Product Specifications

Compare products based on their performance features, curing time, resistance properties, and suitability for your facility.

Step 4. Budget and Quantity

Calculate the amount of paint required based on surface area and factor in your budget, balancing quality and affordability.

Application Tips for Industrial Floor Paint

Proper application techniques ensure your industrial floor paint achieves optimal durability and performance:

Surface Preparation

Clean thoroughly, remove grease and debris, repair cracks, and apply a quality primer to enhance adhesion and durability.

Use Recommended Tools

Rollers or sprayers ensure even paint coverage. Select appropriate equipment based on paint type and facility size.

Follow Manufacturer Guidelines

Adhere strictly to drying times, temperature, and humidity conditions provided by the manufacturer for best results.

Epoxy Catalyst, Epochem® 205, 5kg

Frequently Asked Questions

1. What type of industrial floor paint is best for heavy machinery?

Epoxy-based floor paints are ideal for heavy machinery areas, providing strong resistance to abrasion, impact, and chemical spills.

2. How do I estimate how much floor paint I need?

Calculate your floor’s total area (length × width) and divide by the coverage rate specified on the product label (typically in square meters per liter). Always purchase slightly more than estimated for touch-ups and adjustments.

3. Can industrial floor paint be applied outdoors?

Yes. Select paints specifically designed for outdoor use, such as polyurethane coatings, as they offer UV resistance and durability under changing weather conditions.

4. How long does industrial floor paint take to dry and cure?

Most industrial floor paints dry within 12-24 hours for light traffic. However, full curing (maximum hardness and chemical resistance) typically takes 3-7 days depending on product type and environmental conditions.

5. Where can I buy quality industrial floor paint in Nigeria?

You can purchase premium-quality industrial floor paints and application accessories from GZ Industrial Supplies, offering professional advice, competitive prices, and nationwide delivery.

Related Articles

The Best Floor Paint for Different Types of Flooring

The Science of Floor Paint: How it Works and What to Expect

Conclusion

Choosing the right industrial floor paint is essential for ensuring durability, safety, and long-term cost-effectiveness. By considering factors such as surface type, environmental conditions, chemical resistance, and application methods, businesses can invest in a coating that enhances both aesthetics and functionality. Proper preparation and maintenance further extend the lifespan of your industrial floors, preventing premature wear and tear

For high-quality industrial floor paints that meet the toughest demands, visit GZ Industrial Supplies. We offer a wide range of durable, chemical-resistant, and high-performance coatings tailored to your needs. Browse our collection today and give your floors the protection they deserve!

Recent Posts

-

The Ultimate Guide to Understanding the Difference Between Ethylene Glycol and Propylene Glycol

Introduction Glycols are versatile compounds widely used across various industries, from automotive …Apr 16, 2025 -

What are Agricultural Machinery

Introduction Agricultural Machinery is also used to improve the wide range of production prac …Apr 14, 2025 -

The Best Electrical Wire in Nigeria 2025 (Updated)

Introduction Electrical wires are the basic unit of every electrical system. Electrical wires …Apr 14, 2025