How to Choose the Right Hydraulic Jack for Your Workshop

Introduction

Hydraulic jacks are essential tools in any workshop, offering powerful and reliable lifting solutions for a range of tasks. Whether you're lifting cars, heavy machinery, or other equipment, choosing the right hydraulic jack is crucial for safety, efficiency, and ease of use.

This guide will help you understand the different types of hydraulic jacks and the key factors to consider when selecting the ideal jack for your workshop's needs.

Read more...The Best Hydraulic Jacks for Industrial Applications

Ingco Hydraulic bottle jack 20 Ton HBJ2002

Key Takeaway

- Prioritize Safety Features: Look for jacks with built-in overload protection, safety valves, and solid base plates for stable support during operation.

- Check for Durability and Build Quality: Industrial workshops need jacks made from heavy-duty steel or cast iron, with corrosion-resistant coatings and reinforced components for longevity.

- Portability and Storage Matter: If you move tools often or have limited space, opt for a hydraulic jack that is compact, lightweight, and easy to transport or store.

- Maintenance and Support Availability: Choose reputable brands that offer easy-to-maintain jacks and have accessible replacement parts and local service support—especially important in Nigeria’s industrial market.

Understanding Hydraulic Jacks

Hydraulic jacks operate by using fluid pressure to generate a lifting force, making them capable of lifting heavy loads with minimal effort. Here’s a quick overview of the most common types of hydraulic jacks:

Bottle Jacks:

Known for their vertical design, bottle jacks are compact and capable of lifting heavy loads. They are ideal for trucks and heavy machinery due to their high lifting capacity.

Floor Jacks:

These jacks are designed with a long handle and a horizontal piston, making them easy to slide under vehicles. They are commonly used in automotive workshops for their versatility and ease of maneuverability.

Scissor Jacks:

While not purely hydraulic, scissor jacks use a mechanical screw mechanism and are often combined with hydraulic elements. They are compact and suitable for lighter vehicles or occasional use.

Trolley Jacks:

These heavy-duty jacks are designed for industrial and professional use, offering a combination of high lifting capacity and stability.

High-Lift Jacks:

Built for extreme conditions, high-lift jacks are used for off-road vehicles and heavy equipment, offering a wide range of lifting heights.

ENERPAC 50 Ton, Hydraulic Cylinder and Hand Pump Set

Key Features of Hydraulic Jacks

- Load Capacity: The maximum weight the jack can safely lift.

- Lifting Range: The range of heights the jack can achieve.

- Material and Build Quality: Durability and construction materials like steel or aluminum.

- Safety Mechanisms: Features like overload protection and safety valves.

Assessing Your Workshop Needs

Before choosing a hydraulic jack, it's essential to assess the specific needs of your workshop:

Determine the Type of Vehicles or Machinery:

Consider the weight and size of the vehicles or machinery you'll be lifting. For example, a light-duty bottle jack may suffice for a small car, while a heavy-duty floor jack is better suited for trucks and larger equipment.

Identify the Lifting Requirements:

- Maximum and Minimum Height Requirements: Ensure the jack has a sufficient lifting range to accommodate the highest and lowest points you need to reach.

- Stability and Space Considerations: Your workshop's space can affect which jack type is most suitable. Floor jacks and trolley jacks often require more room for maneuvering compared to bottle jacks.

Read more...Troubleshooting Common Hydraulic Jack Issues

Key Factors to Consider When Choosing a Hydraulic Jack

Selecting the right hydraulic jack involves weighing several factors:

Load Capacity:

Always choose a jack with a load capacity that exceeds the heaviest item you'll be lifting. For safety, select a jack with a capacity at least 20-30% greater than your heaviest load.

Lifting Range:

Ensure the jack’s lifting range suits your needs. Some vehicles, like SUVs and trucks, may require a higher lifting range compared to standard cars.

Construction and Durability:

Look for jacks made of high-quality materials like steel or aluminum. Steel jacks offer durability, while aluminum jacks are lighter and easier to maneuver.

Portability and Maneuverability:

If your workshop requires frequent movement of the jack, opt for models with wheels and handles. Floor jacks and trolley jacks are typically easier to move around.

Safety Features:

Safety should be a top priority. Look for jacks with built-in safety valves, locking mechanisms, and overload protection to prevent accidents during operation.

INGCO Hydraulic bottle jack 10Ton (HBJ1002)

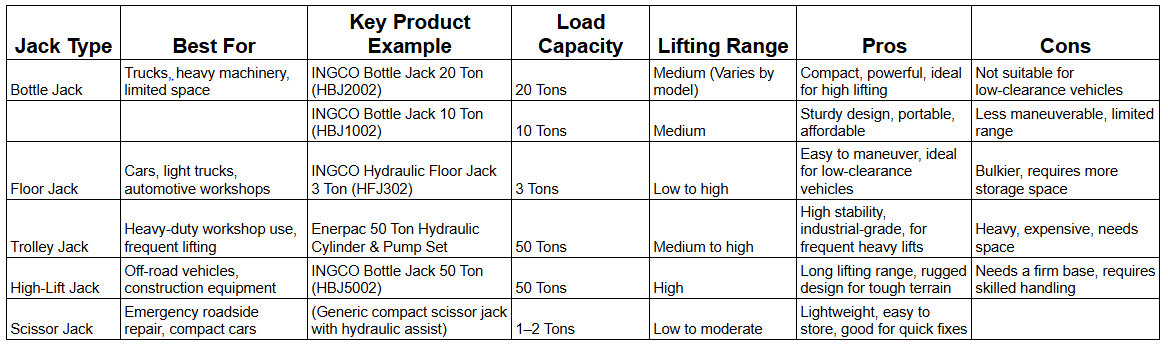

Comparison Table: Choosing the Right Hydraulic Jack for Your Workshop

Read more...Choosing the Right Hydraulic Power Pack: A Guide for Different Bolting Tools and Applications

Types of Hydraulic Jacks and Their Best Uses

Understanding the different types of hydraulic jacks and their specific applications can help you select the best tool for your workshop:

Bottle Jacks:

Best For: Heavy-duty lifting, trucks, and machinery.

Advantages: High lifting capacity, compact size, and simple design.

Drawbacks: Limited lifting range and not ideal for low-clearance vehicles.

Ideal Use: In workshops where high lifting power is required but space is limited.

Floor Jacks:

Best For: General automotive use, low-clearance vehicles.

Advantages: Wide lifting range, easy to maneuver, and suitable for a variety of vehicles.

Drawbacks: Heavier and bulkier than other jacks.

Ideal Use: Automotive workshops that require versatile lifting solutions for cars and light trucks.

Scissor Jacks:

Best For: Emergency use, small cars, and light-duty lifting.

Advantages: Compact, lightweight, and easy to store.

Drawbacks: Lower lifting capacity and less stable than other jacks.

Ideal Use: Suitable for personal vehicle use or in workshops where space is extremely limited.

Trolley Jacks:

Best For: Professional and industrial use.

Advantages: High lifting capacity, stable base, and suitable for frequent use.

Drawbacks: Requires more storage space and can be heavier.

Ideal Use: Workshops that deal with heavy equipment and require a stable and reliable lifting tool.

High-Lift Jacks:

Best For: Off-road vehicles, heavy equipment, and situations requiring a high lifting range.

Advantages: Extensive lifting range and versatility.

Drawbacks: Requires careful handling and a secure base for safe use.

Ideal Use: In workshops or situations involving off-road vehicles or specialized machinery.

Hydraulic Floor Jack 3Ton INGCO (HFJ302)

Proper Maintenance of Hydraulic Jacks

To ensure the longevity and safe operation of your hydraulic jack, regular maintenance is essential:

Regular Inspection:

Inspect your jack for any signs of wear, damage, or leaks. Check the hydraulic fluid level and refill if necessary.

Lubrication:

Regularly lubricate moving parts like wheels, hinges, and pistons to ensure smooth operation and prevent rust.

Fluid Replacement:

Replace hydraulic fluid periodically to maintain optimal performance. Use the manufacturer's recommended fluid type.

Storage:

Store the jack in a clean, dry place when not in use to prevent rust and damage. Keep it upright to avoid leaks.

Safety Tips for Using Hydraulic Jacks

Safety is paramount when using hydraulic jacks. Here are some key safety tips:

Use on a Level Surface:

Always use the jack on a flat, stable surface to prevent tipping.

Secure the Load:

Use jack stands to support the vehicle after lifting it with the jack. Never rely solely on the jack to hold the load.

Avoid Overloading:

Do not exceed the jack's rated capacity. Overloading can cause jack failure and result in accidents.

Follow Manufacturer Instructions:

Always read and follow the manufacturer's guidelines for operating and maintaining the jack.

Ingco 50Ton Hydralic Bottle Jack (HBJ5002)

Frequently Asked Questions

1. What is the most important factor to consider when choosing a hydraulic jack?

The most crucial factor is the lifting capacity. Ensure the jack can handle the weight of the vehicle or equipment you intend to lift. Consider the type of work you’ll be doing and the lifting height required to choose the right jack for your workshop.

2. How often should I replace the hydraulic fluid in my jack?

Hydraulic fluid should be checked regularly and replaced as needed, typically every 6 to 12 months, depending on usage. Always refer to the manufacturer's guidelines for specific maintenance schedules.

3. Can I use a hydraulic jack on an uneven surface?

No, hydraulic jacks should only be used on a flat, stable surface. Using a jack on an uneven surface can lead to instability, increasing the risk of the jack tipping over or failing.

4. Why is my hydraulic jack not lifting properly?

If your jack is not lifting, it may be due to low hydraulic fluid levels, air trapped in the hydraulic system, or worn seals. First, check and refill the fluid if needed, then bleed any air from the system. If the issue persists, inspect for damage and seek professional repair.

5. How do I safely release the load after using a hydraulic jack?

To safely release the load, slowly turn the release valve to lower the jack. Ensure that the load is securely supported by jack stands before lowering. Never release the jack too quickly, as this can cause the load to drop suddenly, leading to potential accidents.

Related Articles

How to Select the Best Hydraulic Jack for Industrial Use

Hydraulic Jack vs. Mechanical Jack: Which is Better?

Common Hydraulic Jack Problems and How to Fix Them

Conclusion

Choosing the right hydraulic jack for your workshop is crucial for safety, efficiency, and ease of use. At GZ Industrial Supplies, we offer a wide range of high-quality hydraulic jacks suitable for various applications. Whether you're looking for a bottle jack, floor jack, or a specialized high-lift jack, we have the perfect tool for your needs.

Visit GZ Industrial Supplies to explore our selection of hydraulic jacks and take the first step towards enhancing your workshop's lifting capabilities. Our expert team is here to provide advice and help you find the best jack for your specific requirements. Contact us today to learn more about our products and how we can support your heavy-duty lifting needs!