Industrial Drilling Machines: Boosting Productivity and Efficiency

Key Takeaway

Industrial drilling machines are indispensable power tools that significantly enhance productivity and efficiency across various industries by providing precision, versatility, and automation, ultimately contributing to cost savings and improved product quality. They are like superheroes in the industrial world. They're the key to getting more work done quickly and efficiently. In factories and manufacturing they make work faster. That's where these machines come in. They help us build machines and also useful in repairs in the quickest and most efficient way possible.

Buy Online... Diamond Core Drilling Machine SCY-18/2EBM Cayken

Introduction

In the world of industry and manufacturing, boosting productivity and efficiency is a constant challenge and "Industrial Drilling Machines" are powerful tools that helps companies make things faster and better. Whether it's building products, constructing buildings, or creating metal parts, industrial drilling machines are the superheroes of production.

Drilling machines offer numerous benefits to industries. They provide precision and accuracy in hole drilling, ensuring consistent hole dimensions. This precision enhances productivity and efficiency, as drilling machines can complete tasks faster than manual methods. They are versatile and adaptable for various materials and applications, from metalworking to woodworking. Automation features reduce the need for constant operator intervention and minimize the risk of errors. These machines contribute to cost savings by reducing material waste and labor costs, making them cost-effective in the long run. In addition, their safety features, customizability, and quality control capabilities make them essential tools in modern manufacturing and production processes, ultimately improving product quality and streamlining operations.

In this exploration, we'll dive into the world of these drilling machines, discovering the various types like cordless drilling machine, corded drilling machine and pneumatic drilling machines, and magnetic drilling machines. We will also discuss how they're the key to not only meeting but exceeding production goals. From busy factories to precision metalwork, these machines have evolved and adapted to make industrial work easier and more efficient. Join us on this journey to uncover the untapped potential of industrial drilling machines and how they're supercharging productivity and efficiency in the world of industry.

Buy Online... DongCheng Magnetic Drill 2000W 20000N DJC32

Benefits of Industrial Drilling Machines

Industrial drilling machines have revolutionized the manufacturing and construction sectors by offering an array of benefits that significantly enhance productivity, efficiency, and the quality of work. Industrial drilling machines offer many benefits that can boost productivity and efficiency in these sectors. Here are some key advantages of these powerful tools:

Precision and Accuracy:

Industrial drilling machines are engineered to deliver pinpoint precision and accuracy. They can create holes with a level of precision that manual drilling methods simply cannot match, ensuring high-quality results and reducing errors and waste. This is crucial in industries where exact specifications are vital, such as aerospace, automotive, and electronics manufacturing.

Increased Productivity:

These machines can operate at high speeds and perform multiple tasks, such as drilling, tapping, reaming, countersinking… quickly and consistently. Unlike manual labor, they don't experience fatigue or variations in work quality. This results in a substantial increase in productivity, allowing companies to complete projects faster and more efficiently.

Versatility and Adaptability:

Industrial drilling machines come in a variety of types and sizes, making them versatile and adaptable to a wide range of applications and materials. Whether you need to drill holes in metals, wood, plastics, or other materials, there's a specialized drilling machine for the job. They can handle tasks from simple holes to complex machining operations. Industrial drilling machines can also be customized and equipped with various accessories and attachments to meet specific needs and preferences.

Automation Features:

Many modern industrial drilling machines come equipped with automation features, including computer numerical control (CNC). These features allow for precise control over the drilling process, including speed, depth, and hole placement. Automation reduces the need for human intervention, improving accuracy as well as increasing efficiency and repeatability.

Consistency and Quality Control:

Consistency in product quality is a hallmark of industrial drilling machines. Once a machine is programmed for a specific task, it consistently produces identical results. This is vital in industries where uniformity and precision are essential, such as in the creation of aerospace components and medical devices. Industrial drilling machines can also monitor and adjust the drilling parameters, such as speed, feed, depth, pressure, etc., to optimize the drilling conditions and prevent damage or defects.

Safety and Cost-Effectiveness:

Industrial drilling machines are designed with safety in mind. They reduce the risks associated with manual drilling, which can lead to accidents and injuries. Additionally, while the initial investment in these machines may be significant, their long-term cost-effectiveness becomes evident. Reduced labor costs, increased productivity, and the minimization of errors translate into substantial savings over time.

Buy Online... Cayken Diamond Core Drilling Machine SCY 26/3EBM

Applications of Drilling machines in Various Industries

Industrial drilling machines find widespread use in various sectors due to their adaptability, precision, and efficiency. Here are some of the key applications of these machines in different industries:

Manufacturing and Production:

Industrial drilling machines are the backbone of manufacturing and production industries. They are employed to create precise holes and cavities in a wide range of materials, including metals, plastics, and composites. Drilling machines can also perform other operations, such as tapping, reaming, countersinking, counterboring, spot facing, etc., to improve the quality and accuracy of the holes. Whether it's for creating parts, molds, or assembling components, drilling machines are crucial in ensuring product quality and consistency.

Aerospace and Automotive:

In the aerospace and automotive industries, precision is very important. Drilling machines play a critical role in creating holes for fasteners, rivets, and other components. They are also used in the machining of aircraft and automotive parts, ensuring that everything fits together perfectly. This precision and efficiency help enhance the safety and performance of vehicles and aircraft.

Construction:

Construction sites benefit from industrial drilling machines for tasks such as creating holes for anchor bolts, dowels, and conduits. These machines are used to drill into concrete, stone, or masonry, providing the structural integrity needed for buildings, bridges, and other infrastructure projects. Drilling machines can also be used for demolition purposes by breaking or cutting through concrete or other hard materials. They can be portable or stationary depending on the size and type of the hole required.

Woodworking and Carpentry:

In woodworking and carpentry, drilling machines are essential for creating holes for screws, dowels, and other fasteners. They are used to join wood pieces securely and accurately, resulting in strong and durable furniture, cabinetry, and other wooden products. They can also be used to create decorative patterns or designs on wood surfaces by using different types of drill bits. Operations on wood materials, such as boring, countersinking, chamfering, shaving, milling, deburring etc., to improve the appearance and functionality of the wood products are made much easier using industrial drilling machines.

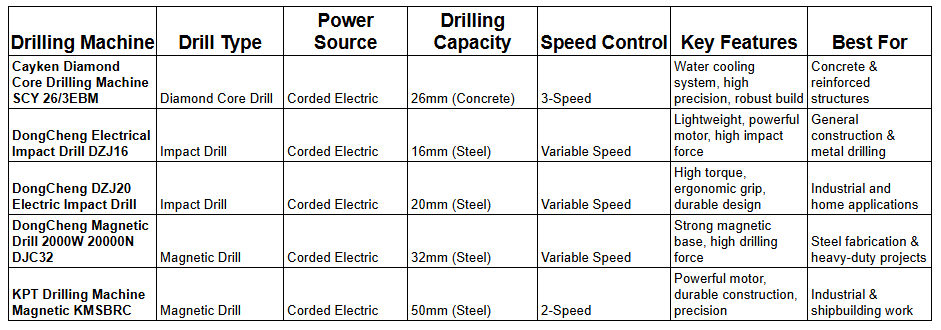

Comparison of Industrial Drilling Machines: Performance & Key Features

Best Drilling Machine Brand

When it comes to industrial drilling machines, choosing the right brand is essential to ensure high performance, reliability, and longevity. Three brands that have earned a stellar reputation in the industry are Cayken, Dongcheng and KPT. Let's delve into the standout products from these manufacturers:

Cayken:

Cayken is a high-tech enterprise that specializes in producing diamond drilling machines, wall cutting machines, magnetic drills, and other industrial drilling machinery. Cayken’s drilling machines offer many advantages, such as high precision and accuracy, high speed and productivity, versatility and adaptability, automation and reliability, consistency and quality control, safety and cost-effectiveness. Some of the popular products of Cayken are:

Diamond Core Drilling Machine SCY-18/2EBM Cayken:

This is a handheld diamond core drill that can drill holes up to 18mm in diameter in various materials, such as concrete, brick, stone, rock, tile, etc. It has a powerful 1800W motor that can operate at 1400r/min. It has a three speed gear regulator that can adjust the speed according to the material and hole size. It has a soft start function that can prevent the drill from jumping or slipping. It has an overload protection system that can protect the motor from damage.The SCY-18/2EBM Cayken offers precise control and excellent drilling performance, making it a top choice for professionals who require accurate and efficient hole boring.

Diamond Core Drilling Machine SCY-68HD Cayken:

This is a heavy-duty diamond core drill that can drill holes up to 68mm in diameter in various materials, such as concrete, reinforced concrete (RC), brick, stone, rock, tile, etc. It has a powerful 2200W motor that can operate at 600r/min. It has an electronic stepless speed-regulation that can adjust the speed according to the material and hole size. It has a mechanical clutch that can prevent the drill from jamming or breaking. This Cayken drilling machine is a go-to tool for construction and industrial projects where reliability is paramount.

Cayken Diamond Core Drilling Machine SCY 26/3EBM:

This is a multifunctional diamond core drill that can perform various operations, such as drilling, tapping, reaming, countersinking, counterboring, spot facing, etc., on various materials, such as metal, wood, plastic, concrete, etc. It has a powerful 2600W motor that can operate at 230r/min or 500r/min. It has a three-speed gear speed regulation. It has an overload protection system that can protect the motor from damage as well as a guide way that can ensure accurate angled hole drilling. Overall it offers precise speed control, ergonomic handling, and the ability to adapt to a wide range of drilling scenarios, making it a versatile solution for your drilling needs.

Buy Online... Diamond Core Drilling Machine SCY-68HD Cayken

Dongcheng

Dongcheng is a high-tech enterprise that specializes in producing various types of power tools and related spare parts, which are widely used in the fields of building construction, home decoration, stone industry, shipbuilding and water conservancy projects. Dongcheng has over 20 series and more than 100 models of drilling machines that cater to diverse needs and applications. Three of the popular products of Dongcheng are:

DongCheng Electrical Impact Drill DZJ16:

This is a handheld electric impact drill that can drill holes up to 16mm in diameter in various materials, such as concrete, brick, stone, rock, tile, etc. It has a powerful 710W motor that can operate at 3000r/min.. It has a soft start function that can prevent the drill from jumping or slipping and an ergonomic design that can reduce fatigue and increase comfort.

DongCheng DZJ20 Electric Impact Drill:

This is a heavy-duty electric impact drill that can drill holes up to 20mm in diameter in various materials, such as concrete, reinforced concrete, brick, stone, rock, tile, etc. It has a powerful 720W motor that can operate at 2800r/min. It has a rubber-covered handle that can provide a better grip and control, plus an adjustable speed, forward and reverse rotation function that can ensure high efficiency.

DongCheng Magnetic Drill 2000W 20000N DJC32:

This is a corded magnetic drill machine that can use broach cutters to create holes in various metal materials, such as metal plates or pipes. It has a powerful 2000W motor that can operate at different speeds depending on the material and hole size. It has a high holding power of magnetic base for better grip on horizontal or vertical surfaces. It has an internal coolant feed system for better cutting action and longer tool life. It has a safety clutch function and an overload protection function to ensure safe and reliable use. It also has an electronic constant speed function to maintain consistent power output as well as a professional quality aluminum alloy die-cast base and high-quality gears for durability.

DongCheng Electric Impact Drill 13mm, 500W DZJ02-13

KPT:

Kpt is a leading manufacturer of power tools and accessories in India. Kpt offers a wide range of products for various applications, such as metal working, wood working, construction, gardening, etc. Kpt’s products are known for their durability, performance, quality, and innovation. Kpt’s products are also certified by various national and international standards and agencies.

KPT Drilling Machine Magnetic KMSBRC:

The KMSBRC is a magnetic drilling machine that's highly regarded for its performance. It features strong magnetism for secure attachment to metallic surfaces, ensuring stability and precision during drilling. KPT Drilling Machine Magnetic KMSBRC: This is a heavy-duty magnetic drill machine that can use broach cutters to create holes in various materials, such as metal plates or pipes. It has a powerful 1100W motor that can operate at 270r/min. It has a high holding power of magnetic base for better grip on horizontal or vertical surfaces. It has an internal coolant feed system for better cutting action and longer tool life. It also has a stabilizing rod for setting offset levels. With excellent durability and ergonomic design, this KPT drilling machine is a reliable choice for professionals in metalworking and fabrication.

Cayken, Dongcheng and KPT are known for their commitment to quality and innovation in the industrial drilling machine sector. The models mentioned above are just a glimpse of their extensive product lines, which cater to diverse drilling needs across various industries. When you opt for these reputable brands, you're making a choice that prioritizes performance, durability, and precision.

Customization and Versatility of Drilling Machines

Industrial drilling machines are prized for their adaptability and ability to cater to a wide array of drilling needs. They can be customized and adapted to different hole sizes and shapes, as well as specialized drilling applications. Some of the ways that drilling machines can achieve customization and versatility are:

Adjustability for Different Hole Sizes and Shapes:

One of the key advantages of industrial drilling machines is their capacity to create holes of varying sizes and shapes. They can use different types of drill bits to create holes with different diameters and depths. Drill bits are cutting tools that have a spiral or helical shape and a pointed tip that can penetrate the material. Drill bits can be made of various materials, such as high-speed steel, carbide, diamond, etc., depending on the hardness and abrasiveness of the material to be drilled. This adaptability is particularly valuable in manufacturing, where products often have unique specifications. These machines can be easily adjusted to produce holes of different diameters, depths, and angles, ensuring that each product adheres to precise engineering standards.

Specialized Drilling Applications:

Industrial drilling machines come equipped with various attachments and tools to handle specialized drilling applications. For instance, in metalworking, countersinking and counterboring tools can be added to create recessed holes for fasteners. Woodworking drilling machines can feature bits that are ideal for specific joinery techniques like mortise and tenon joints. These specialized attachments enhance the versatility of drilling machines, making them suitable for a broad spectrum of tasks across industries.

In essence, the ability to customize drilling parameters and utilize specialized drilling accessories empowers industrial drilling machines to adapt to a multitude of tasks. This makes them invaluable tools for industries that demand flexibility and precision in their operations.

Buy Online... DongCheng DZJ20 Electric Impact Drill

Frequently Asked Questions

Q1 What is a drilling machine?

A power tool called a drilling machine is used to make cylindrical holes in a workpiece. A high-speed rotation and pressing of the tool bit into the workpiece result in the creation of a cylindrical hole that either goes partially through the part (blind hole) or completely through it (through hole).

Q2 What are the tools of a drilling machine?

Drilling tools can be further divided into subcategories such as step drills, oil hole drills, crankshaft drills, extension drills, twist drills, three- and four-fluted drills, and combination drill-and-countersink drills.

Q3 Can you drill holes with a drill driver?

Using an impact driver and a regular hex-shank drill bit, you can make small holes in light-gauge steel and soft wood. However, if you want to produce larger holes than ¼ inch in heavy steel, hardwood, or pressure-treated timber, you'll need a bit designed specifically for impact drivers.

Related Article:

Top Selling Magnetic Drilling Machines in Nigeria

HOW TO USE A MAGNETIC DRILLING MACHINE

Cordless Drilling Machine Price in Nigeria

Readers Also Watched...

Conclusion

Industrial drilling machines are one of the most important and versatile machine tools in a workshop that can perform a variety of tasks on different materials. Industrial drilling machines are essential for modern industries that require high efficiency and quality in their products and services. Industrial drilling machines are the key to boosting productivity and efficiency in various sectors. These precision instruments offer a multitude of benefits, including unparalleled accuracy, increased productivity, versatility, automation features, quality control, safety, and cost-effectiveness. They have evolved into indispensable tools that continue to shape modern production processes.

In today's fast-paced industrial landscape, the demand for efficiency and productivity has never been greater. Industrial drilling machines answer this demand with their ability to bore into a wide array of materials with precision, consistency, and speed. From factories to woodworking workshops, the applications of these machines are far-reaching. Industries like aerospace, automotive, construction, and woodworking have harnessed the power of these machines to drive innovation and push the boundaries of what's possible.

Moreover, the selection of the right brand, like Cayken, Dongcheng and KPT, with their top-notch drilling machine offerings, ensures that these indispensable tools are optimized for efficiency and durability. For more information, or to get some Help making a decision, Contact Gz industrial supplies Today.