Industrial Equipment Maintenance Checklist: Tools and Tips

Introduction

Industrial equipment plays a vital role in manufacturing, construction, and heavy-duty applications. Proper maintenance ensures maximum efficiency, extends the lifespan of machines, and prevents unexpected breakdowns that can lead to costly repairs and downtime.

This guide provides an essential checklist for industrial equipment maintenance, detailing the best tools and techniques to keep your machinery running smoothly. By following this structured approach, businesses can reduce downtime, enhance productivity, and improve workplace safety.

Read more...Maintaining Your Industrial Equipment: Tips and Best Practices

Key Takeaway

- Routine Inspections Are Crucial – Regularly inspecting equipment helps identify potential issues early, preventing costly repairs and downtime.

- Proper Lubrication Extends Equipment Life – Using the right lubricants reduces friction, minimizes wear, and enhances performance.

- Fastening and Adjustments Prevent Failures – Loose bolts and misaligned components can cause malfunctions; routine tightening and adjustments ensure stability.

DongCheng Magnetic drill DJC23

Key Maintenance Categories & Checklist

Routine Preventive Maintenance

Preventive maintenance is essential for catching potential failures before they happen. This includes:

Daily Visual Inspections:

- Check for leaks, loose bolts, and unusual noises.

- Inspect hoses, belts, and moving parts for wear and tear.

- Look for signs of overheating or corrosion.

Lubrication of Moving Parts:

- Apply industrial-grade lubricants to reduce friction and wear.

- Ensure bearings, gears, and mechanical joints are properly greased.

Cleaning and Dust Removal:

- Regularly clean dust, debris, and grease buildup to prevent overheating.

- Use compressed air systems to clear dust from electrical components.

Check Fluid Levels:

- Monitor hydraulic oil, coolant, and lubricants to maintain optimal performance.

- Replace contaminated fluids according to manufacturer recommendations.

Tip: Keep a preventive maintenance log to track completed tasks and identify recurring issues.

Electrical System Maintenance

Electrical faults are a leading cause of industrial equipment failure. Regular electrical maintenance is crucial for preventing unexpected shutdowns and safety hazards.

Inspect Wiring & Connections:

- Look for frayed wires, loose terminals, and exposed cables.

- Ensure electrical insulation is intact.

Test Battery Health:

- Use a multimeter to check voltage stability.

- Clean battery terminals to prevent corrosion buildup.

Check Circuit Breakers & Fuses:

- Ensure breakers are not overloaded or damaged.

- Replace any burnt-out fuses immediately.

Monitor Control Panels & Switchgear:

- Test emergency shutoff switches for proper operation.

- Inspect indicator lights and fault detection systems.

Tip: Schedule quarterly electrical maintenance checks to prevent costly failures.

Cayken Diamond Core Drilling Machine SCY 26/3EBM

Mechanical & Hydraulic System Maintenance

Hydraulic and mechanical failures can lead to severe downtime and expensive repairs. A well-maintained system ensures smooth operation and long service life.

Inspect Belts, Gears, & Bearings:

- Look for cracks, looseness, and excessive wear.

- Apply proper tensioning to prevent slippage.

Check Hydraulic Hoses & Fittings:

- Ensure no leaks, cracks, or bulging hoses.

- Tighten loose fittings to maintain pressure integrity.

Test Pressure & Performance:

- Use hydraulic pressure gauges to verify optimal levels.

- Adjust settings as needed to avoid pressure drops.

Ensure Proper Alignment of Moving Parts:

- Misaligned components cause vibration and mechanical failure.

- Use laser alignment tools for precision adjustments.

Tip: Replace hydraulic filters every 6 months to ensure clean fluid circulation.

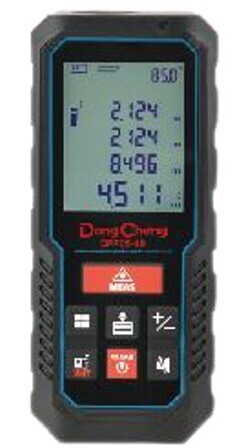

Industrial Equipment Maintenance Checklist: Essential Tools & Tips

Safety System Maintenance

Test Emergency Stop Mechanisms:

- Ensure all emergency shutdown systems function correctly.

- Conduct monthly safety drills for proper response training.

Verify Alarms, Sensors, & Warning Indicators:

- Check motion sensors and overload alarms.

- Ensure all safety beacons and sirens are operational.

Inspect PPE & Safety Gear:

- Ensure helmets, gloves, goggles, and respirators are in good condition.

- Replace worn-out or expired safety equipment.

Assess Fire Suppression Systems:

- Test fire extinguishers, sprinkler systems, and emergency exits.

- Train personnel on fire safety protocols.

Tip: Conduct a safety audit every quarter to ensure compliance with industry safety regulations.

DongCheng Cordless grease gun-DCGG500

Essential Tools for Industrial Equipment Maintenance

Inspection & Diagnostic Tools

Proper inspections help identify early warning signs of equipment failure. Essential diagnostic tools include:

- Infrared Thermometers – Detect overheating components and electrical faults.

- Vibration Analyzers – Identify misalignment, imbalance, or bearing wear.

- Ultrasonic Leak Detectors – Pinpoint air, gas, or vacuum leaks in pneumatic systems.

- Multimeters & Circuit Testers – Measure voltage, continuity, and resistance in electrical systems.

- Borescopes & Inspection Cameras – Allow internal machinery inspections without disassembly.

Tip: Use a preventive maintenance app to log inspection results and flag potential issues.

Lubrication & Cleaning Tools

A well-lubricated machine reduces friction, wear, and overheating. Essential tools include:

- Grease Guns & Oil Dispensers – Apply lubricants to bearings, gears, and joints.

- Industrial Degreasers & Cleaning Solutions – Remove dirt, grease, and corrosion buildup.

- Compressed Air Blowers – Clean filters and vents to prevent overheating.

- Oil Analysis Kits – Test lubricant quality and detect contamination before breakdowns occur.

Tip: Always use manufacturer-recommended lubricants to avoid component damage.

Fastening & Adjustment Tools

Loose bolts, belts, and misalignments cause mechanical failures. Essential tools include:

- Torque Wrenches & Socket Sets – Ensure proper bolt tightening.

- Belt Tension Gauges – Maintain correct belt alignment and tension.

- Alignment Tools – Prevent wear by ensuring precise shaft positioning.

- Bearing Pullers – Remove and replace worn bearings efficiently.

Tip: Inspect all bolts, screws, and fasteners weekly to maintain structural integrity.

Spare Parts & Replacement Kits

To minimize downtime, keep essential replacement parts on hand, including:

- Bearings, Seals, & Gaskets – Replace worn-out mechanical components.

- Hoses & Filters – Maintain fluid flow and air intake efficiency.

- Fuses & Relays – Quick replacement for electrical failures.

- Hydraulic Fluid & Coolants – Prevent overheating and pressure drops.

Tip: Store backup parts in an organized inventory system for quick retrieval.

DongCheng Laser Distance Meter DFF05-80

Best Practices for Effective Equipment Maintenance

Implement a Preventive Maintenance Schedule

- Follow a structured maintenance plan to avoid emergency repairs.

- Use condition-based monitoring tools for real-time performance tracking.

Train Operators on Basic Maintenance

- Educate employees on early warning signs of equipment failure.

- Conduct hands-on training for proper lubrication and minor repairs.

Keep Detailed Maintenance Records

- Log repair history, inspections, and parts replacements.

- Use digital maintenance software for automated tracking and reporting.

Use Predictive Maintenance Technologies

- Implement AI-powered monitoring systems and IoT sensors.

- Analyze historical data to predict potential failures before they happen.

Tip: Businesses using predictive maintenance reduce downtime by up to 30%.

Frequently Asked Questions

1. Why is regular maintenance of industrial equipment important?

Regular maintenance prevents unexpected breakdowns, extends the lifespan of equipment, and ensures safety in industrial operations.

2. What are the essential tools for industrial equipment maintenance?

Some essential tools include lubricants, calibration instruments, cleaning solutions, diagnostic tools, and personal protective equipment (PPE).

3. How often should industrial equipment be inspected?

The frequency of inspections depends on the type of equipment, but a routine check should be conducted weekly or monthly, with comprehensive servicing done quarterly or annually.

4. What are the common signs that industrial equipment needs maintenance?

Signs include unusual noises, overheating, reduced efficiency, fluid leaks, and difficulty in operation.

5. Where can I get high-quality maintenance tools and equipment in Nigeria?

You can find reliable industrial maintenance tools and equipment at GZ Industrial Supplies, offering a wide range of industrial solutions.

Related Articles

Buying Industrial Welding Equipment: What You Need to Know

Guide to Plasma Cutting Machines: Essential Tips for Fabricators

Industrial Floor Paint: Maintenance Tools and Techniques

Conclusion

Maintaining industrial equipment properly is key to optimizing performance, ensuring worker safety, and reducing costly downtime. By following a structured maintenance checklist and using the right tools, businesses can keep their machinery in top condition. Regular inspections, proper lubrication, and timely repairs will extend equipment life and improve efficiency.

Looking for high-quality industrial maintenance tools and equipment? Visit GZ Industrial Supplies for a wide selection of products that keep your operations running smoothly!

Recent Posts

-

Types of Agricultural Machinery and Their Uses

Introduction Agricultural machinery refers to machines used in doing various types of farm work. The …Apr 29, 2025 -

The Best Water Pumps in Nigeria 2025 Reviews

Introduction Water pumps have become so essential in the current world and every household should ha …Apr 28, 2025 -

Top 5 OBD2 Scanners for DIY Car Diagnostics in 2025

Top 5 OBD2 Scanners for DIY Car Diagnostics DIY car maintenance is booming in 2025, and having the r …Apr 26, 2025