Selecting the Best Industrial Paint Mixers for Floor Coatings

Introduction

Industrial floor coatings require thorough and precise mixing to ensure uniform consistency, durability, and strong adhesion. Whether you are working with epoxy, polyurethane, or acrylic coatings, using the right industrial paint mixer can make a significant difference in achieving a smooth, long-lasting finish.

Without proper mixing, floor coatings may suffer from uneven textures, weak adhesion, premature failure, and chemical separation. Selecting the right paint mixer is essential for efficient production, consistent quality, and cost-effective application.

In this guide, we explore:

- Why proper mixing is crucial for industrial floor coatings.

- Types of industrial paint mixers and their best applications.

- Key factors to consider when choosing a paint mixer.

- Best practices for achieving a flawless mix.

Read more...How to Choose the Right Floor Paint: Tips for Durability and Aesthetics

Key Takeaway

- Choose the Right Mixer Type – Different coatings require different mixers; high-speed dispersers are best for large-scale projects, while paddle mixers work for smaller applications.

- Consider Viscosity and Mixing Speed – The thickness of the coating determines the ideal mixing speed. Low speeds work best for thick coatings, while high speeds are suitable for thinner paints.

- Look for Durability and Efficiency – Industrial paint mixers should have strong motors, corrosion-resistant blades, and adjustable speed settings to handle heavy-duty mixing tasks.

Dongcheng Electric Mixer 800W DQU160B

Understanding the Importance of Proper Paint Mixing

Why Mixing Matters in Floor Coatings

Industrial floor paints and coatings contain pigments, resins, and chemical additives that must be properly blended to achieve:

- Even consistency – Prevents streaks, bubbles, or separation.

- Strong adhesion – Ensures the coating bonds well to the substrate.

- Enhanced durability – Improves resistance to heavy traffic and chemical spills.

- Correct curing times – Prevents soft or overly brittle coatings.

Tip: Floor coatings that are not properly mixed can cause early wear, discoloration, and structural failure.

Common Issues Caused by Poor Mixing

If floor paint is not mixed correctly, the final application may suffer from several defects, including:

- Uneven drying – Some areas cure too quickly while others remain tacky.

- Color separation – Pigments settle at the bottom, leading to inconsistent shades.

- Weakened chemical resistance – Floors become more prone to stains and corrosion.

- Bubbling and foaming – Air pockets cause surface imperfections.

Solution: Using the right industrial paint mixer eliminates these problems by ensuring proper blending and aeration control.

Types of Industrial Paint Mixers for Floor Coatings

Selecting the best paint mixer depends on the type of coating, batch size, and viscosity. Below are the most effective mixers used for industrial floor paints:

Read more...The Best Floor Paint for Different Types of Flooring

Handheld Electric Mixers

- Best for: Small-scale and low-viscosity coatings (water-based paints).

- Features: Portable, lightweight, and suitable for small batch mixing.

- Ideal Applications: DIY projects, maintenance touch-ups, and light industrial use.

Pros:

- Affordable and easy to use.

- Quick setup and mixing.

Cons:

- Not suitable for high-viscosity coatings like epoxy or polyurethane.

- Limited power for large-scale projects.

Tip: Always use a spiral mixing paddle for a smoother blend.

Pneumatic Air-Driven Mixers

- Best for: Solvent-based or flammable coatings in hazardous environments.

- Features: Uses compressed air instead of electricity, making it safe for volatile chemicals.

- Ideal Applications: Chemical plants, automotive factories, and heavy-duty coatings.

Pros:

- Explosion-proof and safe for volatile solvents.

- Works well with high-viscosity materials.

Cons:

- Requires a compressed air supply.

- Heavier than electric mixers.

Tip: Best suited for high-production environments where safety is a concern.

Electric Mixer 1800W MX218008 INGCO

Drum & Barrel Mixers

- Best for: Large-scale industrial mixing in factories and production plants.

- Features: Designed to mix high-viscosity coatings directly inside 55-gallon drums or large barrels.

- Ideal Applications: High-volume epoxy, polyurethane, and acrylic coatings.

Pros:

- Handles large batches efficiently.

- Maintains paint uniformity over long production cycles.

Cons:

- Requires dedicated storage space.

- Higher initial investment cost.

Tip: Use for bulk mixing before transferring paint into application containers.

High-Shear Mixers

- Best for: Specialized floor coatings that require intensive pigment and additive dispersion.

- Features: Uses high-speed blades to break down agglomerates, ensuring a smooth and uniform texture.

- Ideal Applications: Anti-slip coatings, textured coatings, and multi-component paints.

Pros:

- Ensures thorough dispersion of pigments and additives.

- Eliminates streaks, bubbles, and inconsistencies.

Cons:

- More expensive than standard mixers.

- Requires precise control to avoid over-mixing.

Tip: Ideal for high-performance and decorative floor coatings where precision is key.

Dual-Action Epoxy Mixers

- Best for: Two-component coatings like epoxy, polyaspartic, and polyurethane floor coatings.

- Features: Designed to thoroughly blend resins and hardeners to prevent uneven curing.

- Ideal Applications: Warehouses, hospitals, commercial buildings, and heavy-duty floor coatings.

Pros:

- Prevents incomplete mixing of two-part coatings.

- Ensures maximum durability and adhesion.

Cons:

- Not necessary for single-component coatings.

- Slightly slower mixing time due to its precise blending process.

Tip: Always follow manufacturer-recommended mixing times to avoid overworking the material.

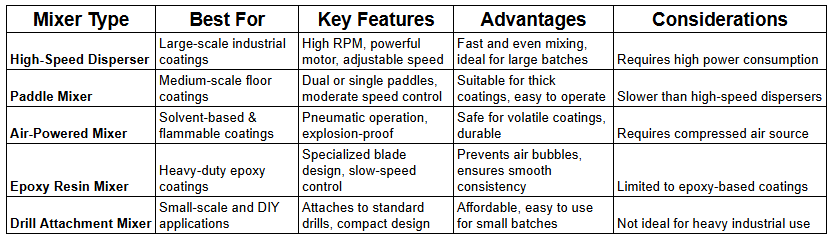

Comparison of Industrial Paint Mixers for Floor Coatings

Key Factors to Consider When Choosing a Paint Mixer

Type of Floor Coating

Not all mixers work for every coating. Choosing the right one ensures optimal mixing and performance:

- Water-based coatings: Handheld or standard electric mixers.

- Solvent-based coatings: Pneumatic mixers (safe for flammable materials).

- Epoxy/polyurethane coatings: Dual-action or drum mixers for uniform blending.

Tip: Check the viscosity level of your floor coating before selecting a mixer.

Batch Size & Production Scale

The volume of paint you need to mix determines the ideal mixer:

- Small-scale applications (DIY or repairs): Handheld mixers.

- Medium-scale industrial projects: Pneumatic or high-shear mixers.

- Large-scale manufacturing: Drum and barrel mixers.

Tip: Overloading a small mixer can lead to inconsistent results—choose a sized mixer for your production needs.

Speed & Motor Power

- Low-speed mixers (200–500 RPM): Suitable for light, water-based paints.

- High-speed mixers (800+ RPM): Required for thicker materials like epoxy and anti-slip coatings.

Tip: Use variable-speed mixers for more control over consistency.

Safety & Compliance

- For solvent-based coatings, use explosion-proof pneumatic mixers.

- Choose dust-free mixing equipment to maintain cleaner workspaces.

Tip: Check if your mixer complies with OSHA and industrial safety regulations for workplace safety.

Dongcheng Electric Mixer 1010W DQU02-160

Best Practices for Mixing Industrial Floor Paints

Correct Mixing Time & Speed

- Under-mixing leads to uneven color distribution and poor adhesion.

- Over-mixing can introduce air bubbles, leading to surface defects.

Tip: Follow the manufacturer’s recommended mixing time to avoid errors.

Using the Right Mixing Attachments

- Paddle mixers – Best for standard coatings.

- Spiral mixers – Ideal for thicker coatings like epoxy.

- Propeller mixers – Used for multi-component coatings.

Tip: Use larger paddles for high-viscosity coatings to improve efficiency.

Cleaning & Maintaining Mixers

- Regular cleaning prevents contamination between batches.

- Lubricate moving parts to extend the lifespan of the mixer.

Tip: Always flush solvent-based coatings out of mixers immediately after use.

Frequently Asked Questions

1. What type of industrial paint mixer is best for floor coatings?

The ideal mixer depends on the paint viscosity and project size. High-speed dispersers work well for large-scale applications, while handheld or paddle mixers suit smaller jobs.

2. How do I determine the right mixing speed for floor coatings?

Mixing speed should align with the paint's viscosity and formulation. Low speeds prevent bubbles in thick coatings, while higher speeds ensure smooth consistency for thinner coatings.

3. What are the key features to look for in an industrial paint mixer?

Look for durability, adjustable speed settings, blade design, and compatibility with different coating types to ensure efficient and uniform mixing.

4. Can I use the same mixer for different types of coatings?

Yes, but cleaning is essential between uses to prevent contamination. Some mixers come with interchangeable blades for versatility.

5. Where can I buy high-quality industrial paint mixers in Nigeria?

You can purchase reliable industrial paint mixers from GZ Industrial Supplies. They offer a range of high-performance mixers suitable for floor coatings. Visit GZ Industrial Supplies for the best selection.

Related Articles

Surface Preparation Methods for Industrial Painting: Ensuring Long-lasting Results

Floor Paint Maintenance: How to Keep Your Floors Looking Their Best

Conclusion

Selecting the right industrial paint mixer ensures smooth application, enhances coating durability, and improves efficiency in floor coating projects. By considering factors such as mixer type, speed control, and compatibility with different coatings, you can achieve high-quality results.

For top-quality industrial paint mixers and floor coating equipment, visit GZ Industrial Supplies. Find the best tools to enhance your coating projects today!

Recent Posts

-

Agricultural Sprayer and its uses

Introduction Agricultural sprayers are a special type of farm equipment used for applying liquid sub …Apr 25, 2025 -

Why Serious Mechanics Are Switching to Japanese-Made Shinano Air Tools

Japanese-Made Shinano Air Tools Key takeaway: Shinano’s tight-tolerance, twin-hammer designs d …Apr 24, 2025 -

Top 10 Hand Tool Brands for Professionals

Introduction When it comes to professional hand tools, quality, durability, and reliability are para …Apr 23, 2025