Surface Preparation of Marine Vessels For Coating

Surface Preparation of Marine Vessels For Coating

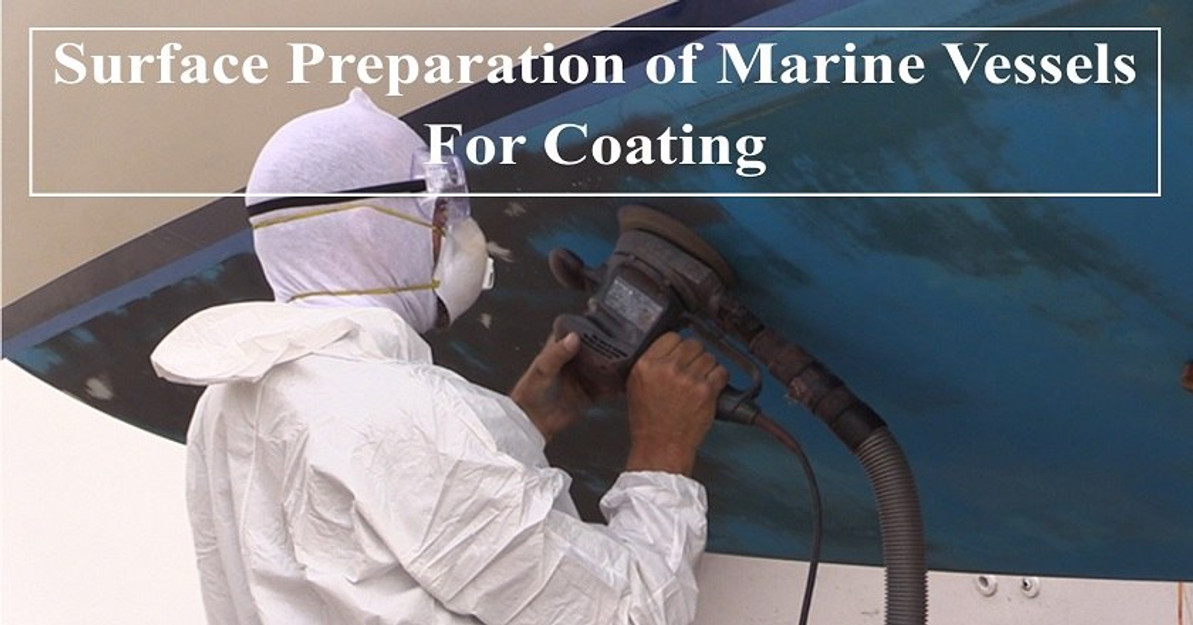

Coating is the most cost-effective way of providing protection for corrosion and to prolong the lifespan of marine vessel and other offshore structures. Paint and preservative coatings can be found on both interior and exterior surfaces of a ship with separate areas being coated differently according to their particular kind of exposure. Before paint can be effective as an anticorrosive, the substrate to which it is to be applied must be thoroughly cleaned to obtain maximum adhesion of paint to steel.

The surface preparation is the most vital aspect of any paint process. The success of any coating system depends on careful and complete preparation of the structure before painting and it is an important factor in achieving high bond strength, lifespan of bonded joints paint, durability and to prevent paint failure.

The surface of the system should be properly prepared before coating the substrate. All cracks, holes and other imperfections which may not allow the paint to adhere or bond well with the substrate should be properly treated. Smooth and an even surface must be achieved on the substrate before any paint or coating products should be applied.

Factors To Consider Before Implementing Surface Preparation of Vessel

- The first thing to consider is to identify the composition or the type of substrate you want to coat because different substrate materials will require different types of adhesives for bonding and different methods of surface preparation; this is important to ensure the chosen pretreatment procedure will effectively prepare the surface without damaging it. Some surfaces may require nothing more than having the dust brushed away or to wash it with light detergent while others may require elaborate surface preparation procedures prior to bonding. Whatever materials you work with, it’s a good idea to equip yourself with a comprehensive knowledge of surface preparation.

- The second factor is to identify the type of contaminant on the surface of substrate which could be grease, soil, oil, dirty, living organize like algae or other unwanted bodies. This will help to determine the most effective and safest method for removing the debris or contaminants.

- The type of substrate – Maintenance or new coating because this will also determine the type of surface preparation method to use.

Ensure Temperature & Humidity Control: The temperature and humidity where the substrate is located should be put into account; it is must be in a highly controlled environment Proper surface preparation enhances adhesion of the film to the surface. When coating a surface prepared by blasting, the real issue is not time: the key criterion is that the steel temperature shall always be at least 3 °C (5 °F) higher than the calculated dew point. This safety margin is sufficient for all types of coatings. Consideration of factors such as time, temperature, and humidity must be the responsibility of the inspector in the course of surface preparation and coating of the substrate. No final blast cleaning or coating application shall be done if the relative humidity is more than 85 % and when the steel temperature is less than 3 °C above the dew point. No coating shall be applied or cured at temperatures below 0 °C of the coating selected and the expected service life of the coating system.

The Following Factors are Caused by Moisture:

It has been estimated that 60 to 80% of all premature coating failures are caused either completely or partially by inadequate or improper surface preparation.

Common surface preparation defects include flash rust, which occurs if the surface is subjected to environmental factors before the first coat is applied, and prevents the coating from adhering properly to the substrate surface after blasting. The presence of high humidity conditions often causes the formation of rust bloom on the metal surface, resulting in blistering and delamination.

- High atmospheric humidity enhances condensation of moisture on the surface.

- Condensation can result in flash rust that causes the coating to fail.

- Surface condensation, if painted over, may result in blistering and delamination.

Priming

Priming is the final stage of surface preparation before the coating. Primer or undercoat is a preparatory coating put on materials before painting. Priming ensures better adhesion of paint to the surface, increases paint durability, and provides additional protection for the material being painted.

It is very important to apply the primer as soon as possible after the surface has been prepared. This is to protect the freshly blasted surface as corrosion starts immediately after the surface is prepared and the primer alleviates this. Apply the primer to a clean, dry surface by brushing or spraying. The primer should be applied as a thin coat. Allow the primer to air dry for 30 – 60 minutes. It is important that during this time airborne contaminants do not settle on the surface as this could affect the adhesion of the topcoat.

For more detailed insights on topics related to Surface Preparation of Marine Vessels For Coating and how to choose the right marine paint to apply, visit GZ Industrial Supplies Limited, or contact this numbers 08053390163, 08058696458.

Recent Posts

-

Top 10 Hand Tool Brands for Professionals

Introduction When it comes to professional hand tools, quality, durability, and reliability are para …Apr 23, 2025 -

HOW DOES CORROSION INHIBITOR WORK

Introduction Corrosion has posed a lot of problems to various companies and industries; by interfer …Apr 22, 2025 -

The Ultimate Guide to Understanding the Difference Between Ethylene Glycol and Propylene Glycol

Introduction Glycols are versatile compounds widely used across various industries, from automotive …Apr 16, 2025