Transformer Sizing: How to Calculate the Right Capacity for Your Needs

Introduction

Transformer sizing is a crucial step in ensuring that an electrical system runs smoothly and efficiently. Choosing the correct transformer capacity not only helps optimize operational reliability but also reduces energy costs and maintenance needs. Inappropriate sizing can lead to issues like overheating, inefficiencies, and even potential safety hazards. Selecting the right transformer size is a critical step in achieving efficient and safe power distribution across residential, commercial, and industrial applications.

Proper transformer sizing involves understanding the power needs of connected equipment, calculating the total load in kilovolt-amperes (kVA), and factoring in the power factor, efficiency, and potential future expansion. Environmental conditions, such as temperature and altitude, also influence the sizing decision, as they can affect transformer cooling and performance. By taking a systematic approach and utilizing tools like online calculators and manufacturer guides, users can select a transformer with the ideal capacity, ensuring reliable operation, reducing energy losses, and protecting equipment from strain or overload.

This guide provides a comprehensive look at how to accurately calculate transformer capacity based on various needs and applications.

ASTOR TRANSFORMERS 100KVA 33/400KV

Key Takeaway

- Accurate Transformer Sizing Is Essential: Choosing the right transformer capacity ensures efficient power distribution, cost savings, and reliable operation in various applications.

- Understand Load Requirements: Proper sizing depends on understanding the total load in kVA, the power factor, and whether the load is continuous or intermittent.

- Factor in Environmental and Future Load Conditions: Temperature, humidity, and altitude can affect transformer efficiency, as can anticipated future power demand.

- Use the Right Calculations: Transforming total load into kVA with considerations for efficiency and safety margins prevents under- or over-sizing issues.

Understanding Transformer Basics

What is a Transformer?

A transformer is an electrical device that transfers energy between circuits, allowing for voltage adjustments suited to different power needs. In most applications, transformers either step up voltage (increase voltage) or step down voltage (reduce voltage) to match equipment requirements. By transferring electrical energy between circuits, transformers help ensure that machines, tools, or appliances receive the right amount of power safely and efficiently.

Key Types of Transformers

Different transformer types serve unique purposes:

- Step-up Transformers: Used to increase voltage, commonly applied in power generation stations for long-distance power transmission.

- Step-down Transformers: Reduce voltage levels and are often used for residential and commercial power distribution.

- Isolation Transformers: Provide electrical isolation and are widely used for sensitive equipment to prevent interference.

- Autotransformers: Use a single winding that acts as both the primary and secondary coil, making them suitable for low-ratio voltage changes in specific industrial settings.

Basic Terms and Units in Transformer Sizing

To size a transformer correctly, it’s important to understand certain key terms:

- Kilovolt-Amperes (kVA): The apparent power rating, which measures the transformer’s capacity.

- Voltage (V): The electric potential difference applied between two points.

- Current (Amps): The rate at which electricity flows, relevant for determining the load a transformer can handle.

- Load: The amount of power that will be drawn by the devices or equipment connected to the transformer.

MEKSAN Power Transformer 1.5MVA 11.0/400KV

Factors to Consider When Sizing a Transformer

Proper transformer sizing depends on a variety of factors that should be evaluated to ensure efficient and safe operation:

Load Type and Characteristics

Transformers handle different kinds of loads based on application needs. Load type can be either continuous or intermittent:

Continuous Loads: These run for extended periods, such as HVAC systems or lighting in commercial buildings, requiring a transformer that can handle constant power output.

Intermittent Loads: These are only active occasionally or for short bursts, like some machinery in industrial setups.

Another consideration is whether the load is resistive (like heaters) or inductive (such as motors and transformers themselves). Inductive loads often have a lower power factor, requiring more capacity to handle peak demands without overloading.

Total Load Capacity:

The total load represents the maximum power demand, generally measured in kilowatts (kW) or kilovolt-amperes (kVA), that the transformer needs to accommodate. To convert kW to kVA (especially if the power factor isn’t 1), use the formula:

kVA =kW/ Power Factor

Example: For a 500 kW load with a power factor of 0.9, the transformer should have a capacity of:

500/0.9 =555.56 kVa

Voltage Requirements:

The primary and secondary voltage requirements are essential when selecting a transformer. The primary voltage is the input, typically from a power source, while the secondary voltage is the output delivered to the equipment. Selecting a transformer that matches both primary and secondary voltage levels is critical to ensure the correct power output and prevent equipment damage.

Future Expansion Needs:

Anticipating future power requirements can save costs and prevent the need for additional upgrades. If there’s a likelihood of increased demand, it’s wise to factor in extra capacity when sizing the transformer, allowing for scalability and cost-efficiency over time.

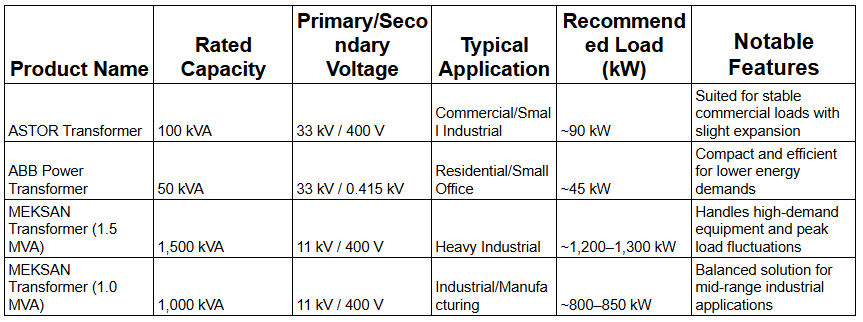

Transformer Comparison Table: Specifications & Applications

Step-by-Step Guide to Calculating Transformer Size

To accurately size a transformer, the following steps outline the fundamental calculations:

Determine Total Load in kVA

Calculate the total power demand by first determining the load in kilowatts (kW) and converting it to kVA using the formula mentioned above. If the power factor is unknown, consult equipment specifications or estimate based on industry averages.

Apply Load Factor and Efficiency Considerations

The load factor reflects the transformer’s actual use compared to its maximum possible load. Accounting for load factor allows for realistic sizing that meets daily power demands without unnecessary capacity. Additionally, consider transformer efficiency (expressed as a percentage) since a transformer loses some energy in the form of heat.

Choose Appropriate Safety Margin

Adding a safety margin to your transformer capacity is crucial to handle any unexpected load increases or spikes. Typically, a 10-25% buffer is added to ensure reliability and longevity, especially in high-demand environments.

ABB Power Transformer 50KVA 33/0.415KV

Calculate Transformer kVA Rating

To calculate a transformer’s kVA rating, you’ll need to know the voltage and current requirements of the connected load. For a single-phase transformer, use the formula kVA = (Voltage × Current) / 1000. For example, a load drawing 50 amps at 400 volts would require a 20 kVA transformer.

For a three-phase transformer, use the formula kVA = (√3 × Voltage × Current) / 1000.

For instance, if the load is 50 amps at 400 volts, it would require approximately 34.64 kVA. It’s also wise to select a transformer with a slightly higher rating than your current needs to allow for future expansion. Calculating the appropriate kVA ensures that your transformer will efficiently handle power demands without risk of overload or failure.

Practical Examples of Transformer Sizing Calculations

Using real-life scenarios can help clarify how to apply these transformer sizing calculations. Here are examples for residential, industrial, and commercial applications.

Residential Application Example

Suppose a small residential building has several basic electrical appliances and systems, including lighting, HVAC, and kitchen equipment, totaling 30 kW. Assuming a power factor of 0.9, the calculation for transformer size would be:

kVA =kW/ Power Factor

kVA= 30kW/0.9

= 33.33kVA

Adding a 20% safety margin for future expansion:

Total kVA with margin=33.33×1.2=40 kVA

Industrial Application Example

For an industrial setup with machinery that collectively requires 250 kW and has a power factor of 0.8, the transformer sizing calculation would be as follows:

kVA =kW/ Power Factor

kVA= 250kW/0.8

= 312.5kVA

With an efficiency rate of 95% and a 25% safety margin:

Account for Transformer Efficiency (95%): Since the transformer operates at 95% efficiency, we need to increase the kVA to compensate for the 5% loss in efficiency:

Adjusted kVA= 312.5/0.95

= 328.95 kVA

Add a 25% Safety Margin for Future Expansion: Now, we add a 25% safety margin to ensure the transformer can handle additional load in the future:

Final kVA with Safety Margin=328.95×1.25=411.19 kVA

Commercial Application Example

In a commercial building with a lighting and HVAC system totaling 80 kW, with a power factor of 0.85, the transformer size can be calculated as follows:

kVA =kW/ Power Factor

kVA= 80kW/0.85

= 94.12kVA

Adding a 15% safety margin:

Total kVA with margin=94.12×1.15=108.24 kVA

Epochem premium Transformer Oil 20L

Common Mistakes to Avoid in Transformer Sizing

When sizing a transformer, avoiding common pitfalls is crucial to ensure efficiency and safety.

Ignoring Power Factor

Power factor plays a vital role in transformer sizing, as it represents the ratio of actual power used by a load to the apparent power. Failing to account for power factor can lead to undersizing, causing excessive strain on the transformer and increasing the risk of failure.

Underestimating Peak Load Demand

Transformers should be able to handle peak loads without overheating or compromising performance. Underestimating peak load can lead to operational interruptions, reduced transformer lifespan, and possible damage. It’s essential to analyze load variations and plan for maximum demand.

Neglecting Environmental Conditions

Environmental factors such as temperature, humidity, and altitude affect transformer efficiency. High temperatures and poor ventilation can cause overheating, while high altitudes reduce air density, affecting cooling. Adjust transformer size if the installation site experiences extreme conditions or requires specialized equipment.

Tools and Resources for Accurate Transformer Sizing

Several tools and resources can support accurate transformer sizing:

Online Calculators and Sizing Tools

Reputable online calculators are available to simplify transformer sizing. These tools allow users to input load details, voltage, power factor, and safety margins to calculate the transformer size. Always use calculators from trusted sources or manufacturers.

Manufacturer Sizing Guides and Support

Transformer manufacturers often provide sizing guides tailored to different applications, considering standard voltage levels, power requirements, and environmental conditions. Consulting these resources or reaching out to technical support can provide added confidence in selecting the right transformer.

Load Analysis Software

Advanced load analysis software allows users to map out load demand variations throughout the day or operational cycle. This data helps determine whether a transformer can meet peak demands, assisting with accurate sizing and future-proofing decisions.

MEKSAN Power Transformer 1MVA 11.0/400KV

Frequently Asked Questions

1. How does transformer sizing impact energy efficiency?

A properly sized transformer operates more efficiently, as it reduces energy losses. Oversized transformers can waste energy, while undersized transformers may overheat and require frequent maintenance.

2. What’s the difference between kVA and kW in transformer sizing?

kVA (kilovolt-amperes) is the apparent power, while kW (kilowatts) is the actual power used. Power factor accounts for the difference between them. Transformer sizing often uses kVA to include both real and reactive power.

3. Why is it essential to consider future load expansion when sizing a transformer?

Considering future expansion helps avoid costly replacements as demand grows. By adding a safety margin for extra capacity, you ensure that the transformer can handle increased loads without risk.

4. How does the environment affect transformer sizing?

High temperatures, humidity, and altitude impact transformer performance by reducing cooling efficiency. Environmental adjustments may be necessary to ensure optimal transformer function.

5. Can I use an undersized transformer temporarily if my load increases?

It’s not advisable, as this can overheat the transformer, reducing its lifespan and potentially causing failures. Choosing a transformer that meets peak demands is safer and more efficient.

Related Articles

How to Choose the Right Surface Maintenance Solutions for Your Needs

Top Transformer Suppliers in Nigeria: Where to Find the Best Prices

Conclusion

Accurate transformer sizing is essential for ensuring reliable power distribution, efficiency, and longevity of electrical equipment. By understanding the basics of transformer types, key factors influencing transformer capacity, and following step-by-step calculations, users can choose the right transformer for residential, commercial, and industrial applications. Factoring in potential future expansion and environmental conditions further ensures that your transformer will remain effective in the long term, avoiding costly maintenance or replacement issues.

Selecting the right transformer capacity is about balancing current needs with long-term reliability and safety. This guide provides the tools and knowledge to make an informed decision, protecting your investment and improving the efficiency of your electrical system.

For more guidance and high-quality transformer supplies, visitGZ Industrial Supplies. Explore a wide range of transformers suited for various applications, along with expert support to help you select the right capacity for your needs.